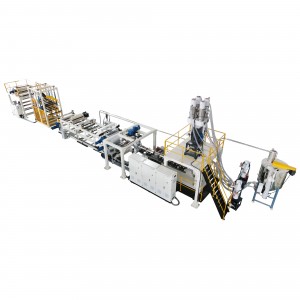

Parallel Twin Screw Extruder PET Sheet Extrusion Line

The lpj-95/48 triple degassing parallel twin screw extrusion line for PET sheet, this line equipped with degassing system, and no need drying and crystallizing unit.

The extrusion line has the properties of low energy consumption, simple production process and easy maintenance. The segmented

screw structure can reduce the viscosity loss of PET resin, the symmetrical calendar roller can improve the cooling effect and increase

the sheet capacity and quality. Multi components dosing feeder can control the percentage of virgin material, recycling material and

master batch precisely. This line can also be equipped with automatic T die and online thickness scanner to form a closed circle to

ensure the sheets thickness more uniformed. The online side trim granulator and pipeline conveying system can convey the side edges

to the front extruder automatically.

Advantages of the line

1)Gravimetric dosing system for raw material handling, can realize proportionally precise mixing of several types of raw materials components.

2) Fully automatic double pillars four stations backflush type hydraulic screen changer

3)By changing roller calendars, the line can produce both high gloss smooth finish sheet and also matte finish sheets and

other textured sheets as customized.

4) France SCANTECH thickness scanner for thickness measuring automatically.

5)The online side trim granulator and pipeline conveying system can convey the side edges to the front extruder automatically.

6)Sheets accumulator design for higher line speed

7)Effective energy saving technology with very low energy consumption.

8)Whole line adopts fully automatic Siemens PLC touch screen control; the electronic control equipment effectively optimizes the

whole line operation and achieves high quality and high output.

| Main extruder model | LSJ-120 | LSJ-150 | LPJ-75 | LPJ-95 |

| Co-extruder model | LSJ-65, LSJ-75 | LSJ-65, LSJ-75 | LPJ-52 | LPJ-52 |

| Suitable material | PET PP PS PLA PBAT, granules, flakes etc | |||

| Product width | 700-1500mm | 700-1500mm | 700-1500mm | 700-1500mm |

| Product thickness | 0.15-1.5-2mm | 0.15-1.5-2mm | 0.15-1.5-2mm | 0.15-1.5-2mm |

| Max capacity | 300-400kg/h | 500-800kg/h | 300-450kg/h | 500-800-1000kg/h |

| Product structure | Mono layer, A/B/A 3 layers, A/B 2 layers, or multi-layers | |||