Wholesale Polypropylene Sheet Extrusion Line Factory – HDPE Geocell Sheet/T-grip Sheet Extrusion Line – Leader

Wholesale Polypropylene Sheet Extrusion Line Factory – HDPE Geocell Sheet/T-grip Sheet Extrusion Line – Leader Detail:

HDPE Geocell is a new type of high-strength geosynthetics, which is popular in domestic and abroad. It is a kind of three-dimensional network structure shaped by high-strength HDPE sheets through high power ultrasonic welding. It is easily folding and convenient for transportation. During the construction, the geocell sheets can be pull into a network and launched into a three dimensional honeycomb grid. As it filled in soil, macadam, concrete or other granules material, constituted to be a construction which has strong side wise restraint and high rate of stiffness.

Main applications of HDPE geocell

Currently, it is being widely used in construction, such as highway, railway, bridge, dyke, shallow river, pipelines and sewer’s support, independent walls, wharf, deserts, beach, and river beds etc.

By changing the roller calendars, it can also produce the HDPE T-grip liner sheets. These sheets consist of a smooth surface and a surface with parallel T-shaped anchors. These anchors are formed directly during extrusion and are an integral part of the sheet. The anchors then remain embedded in the concrete when casting – isolating it from the damaging effects of aggressive elements. HDPE T-Grip Liner also represents an important step forward in the physical properties of buildings in general, whether prefabricated or cast in situ. The elongation at break enables the lining not to break when subjected to stress – unlike the protective coatings realized with paints or others. Additional benefits such as increased load capacity through a low coefficient of friction when used to convey liquids make the liner a cost-effective solution for a wide variety of applications.

Main applications of HDPE T-grip liner

Concrete pipes lining, concrete box culverts lining, chemical tanks, basement and foundations, tunnels and underpasses, drinking water tanks, attics, bridges and viaducts, waste water treatment plants, underground parking, submerged pipes

Main Technical data

| Geocell Sheet Extrusion | T-grip Liner Extrusion | |||

| Model | LMSB-105 | LMSB-120 | LMSB-120 | LMSB-150 |

| Suitable material | HDPE PP | HDPE | ||

| sheet width | 600-900mm | 1200mm-1800mm | 1000-1500mm | 2000-3000mm |

| sheet thickness | 1.1mm, 1.2mm, 1.5mm, 1.8mm | 1.5-4mm | ||

| Max capacity | 250-350kg/h | 500-600kg/h | 400-500kg/h | 500-600kg/h |

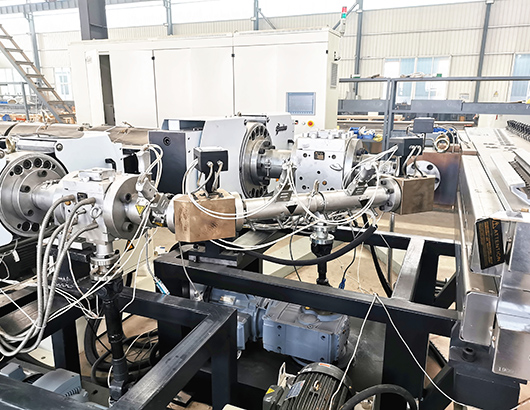

Product detail pictures:

Related Product Guide:

We are also specializing in improving the things management and QC method in order that we could retain terrific edge inside the fiercely-competitive small business for Wholesale Polypropylene Sheet Extrusion Line Factory – HDPE Geocell Sheet/T-grip Sheet Extrusion Line – Leader , The product will supply to all over the world, such as: Colombia, Cologne, Botswana, Ought to any of these products be of curiosity to you, remember to allow us to know. We are going to be satisfied to give you a quotation on receipt of one's in depth specs. We've our private experienced R&D enginners to meet any of one's requriements, We appear forward to receiving your enquires soon'and hope to have the opportunity to work together with you in the future. Welcome to check out our company.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.