Wholesale Pmma Bathtub Sheet Extrusion Line Factory – PMMA (acrylic sheet) GPPS PS PC PETG/APET Sheets Extrusion Line – Leader

Wholesale Pmma Bathtub Sheet Extrusion Line Factory – PMMA (acrylic sheet) GPPS PS PC PETG/APET Sheets Extrusion Line – Leader Detail:

Main features of the line

1) Dehumidifying and drying system for to reduce the moisture of the raw material

2) Gravimetric dosing system for raw material handling is avaliable

3) Advanced screw and barrel structure design can realize the raw material good plasticization and stable pressure and reliable extrusion

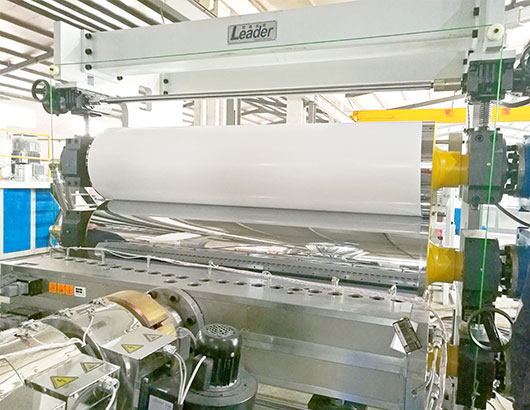

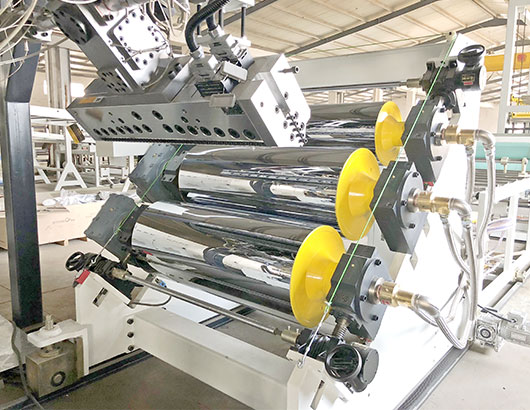

4) By changing roller calendars, the line can produce both high gloss smooth finish sheet and also matte finish sheets and other textured sheets as customized.

5) Advanced technology optimized the extrusion process and result in an excellent and stable products.

6) High flexibility of our lines, suitable for manufacturing a wide range of raw material and products types.

7) Complete automation of the extrusion line saved the labor cost and reduced the maintenance and processing cost as well.

8) Worldwide famous assembly parts, such as SHINI, MOTAN, JC TIMES, NORDSON EDI, SCANTECH, NORD, MAAG, GEFRON, NSK, ABB, SIEMENS etc.

Different applications for such sheets

GPPS PS PC lighting panel is used for the ultra-thin light box, LED flat light panel, poster and advertising decorations. LCD panels are used for the display or computer, laptop, television, and also mobile etc.

PMMA common sheets are widely used for advertising, window and door panels, decoration, handicraft, signage and specimen, showcases and photo frames, building construction, safety barriers/protections, interior design and furniture etc. Electroplate PMMA sheets, widely used for the vacuum plastic mirror etc.

Specifications of the sheets

Sheet width 600mm, 800mm, 900mm, 1220mm, 1400mm, 1500mm, 2100mm or customized

Sheet thickness: 1-6mm-10mm

Sheet structure: mono layer or multi-layers co-extrusion

Sheets colors: Clear, Green, Blue, Smoke, Opal White, Milky White and Diffuser Translucent colors etc.

Main Technical Data

| Model | LSJ-105 | LSJ-120 | LSJ-130 |

| Suitable material | PS GPPS PC PMMA | ||

| Product width | 600-800MM | 1220-1400-1600mm | 2100mm |

| Product thickness | 1-1.5-6-10mm | ||

| Max capacity | 250-300kg/h | 350-450kg/h | 500-600kg/h |

Product detail pictures:

Related Product Guide:

We've got a specialist, effectiveness staff to supply high quality service for our shopper. We always follow the tenet of customer-oriented, details-focused for Wholesale Pmma Bathtub Sheet Extrusion Line Factory – PMMA (acrylic sheet) GPPS PS PC PETG/APET Sheets Extrusion Line – Leader , The product will supply to all over the world, such as: Israel, Seattle, Seattle, Since the establishment of our company, we have realized the importance of providing good quality products and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.