Wholesale Plastic Plate Machinery Supplier – PVC WPC Foam Board / Co-Extrusion Foam Board Extrusion Line – Leader

Wholesale Plastic Plate Machinery Supplier – PVC WPC Foam Board / Co-Extrusion Foam Board Extrusion Line – Leader Detail:

PVC celuka foam board & co-extrusion inner foam boards

PVC crust foam board surface is smooth and the hardness is very high. It is difficult to be scratched. With sound insulation, heat insulation, flame retardant, moistureproof, mouldproof, moth-proofing, not bibulous, good shockproof effect. The color can be permanent.Can be like wood for nail, planing, drilling, sawing etc. widely used in office furniture, kitchen cabinets, bathroom cabinets, and condole roof decoration, building templates etc, which is the good replacement of wood, Aluminum board, composite board, MDF board, polywood board etc.

PVC free foam boards

PVC free foam board, also known as snow board and Andy board, its chemical composition is polyvinyl chloride. The surface hardness of PVC free foam board is common, but with advantages of stable chemical properties, acid and alkali resistance, corrosion resistance, heat insulation and heat preservation etc.. Widely used in advertising display boards, mounting boards, screen printing, computer lettering, advertising signs, exhibition board, sign board, silk screen printing, engraving, electronic instruments packing, album plates etc.

PVC construction formwork boards,building boards

Using pvc waste plastic and wood powder, calcium carbonate and other fillers, this line can also produce PVC construction board, which is a new type of board to replace steel formwork board and bamboo wood plywood board. PVC construction board has many advantages: such as low cost, light weight, reusability, etc. At the same time, the waste can be crushed and reused. The use method of PVC building formwork board is the same as that of bamboo and wood formwork board. Due to its plastic material and special production process, the turnover of PVC building formwork board can be used up to more than 30 times, and the completely crushed boards can still be recycled. Single use cost is relatively low, and it is also environmentally friendly.

Main technical data

| Board type | (semi) celuka foam | Inner foamed co-extrusion | Free foam | |

| Model | SJSZ-80/173 | SJSZ-92/188 | SJSZ-80/173+65/132 | SJSZ-80/156 |

| Suitable material | PVC formula material, wood fiber | PVC formular material | ||

| Product width | 915-1220mm | 2050mm | 1220mm | 1220mm |

| Product thickness | 5-20mm, 3-30mm | 1-10mm, 2-18mm | ||

| Product structure | Mono layer | Mono layer | A/B/A 3-layer co-extrusion | Mono layer |

| Max capacity | 350-450kg/h | 500-700kg/h | 500-650kg/h | 300-350kg/h |

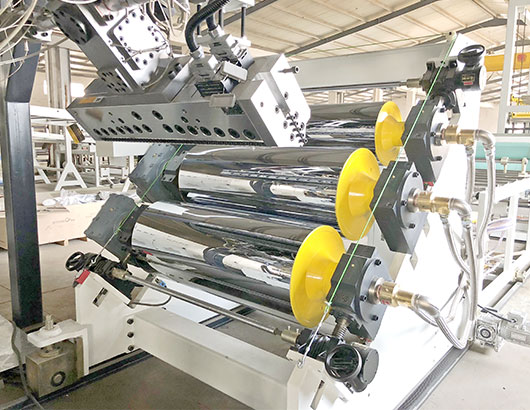

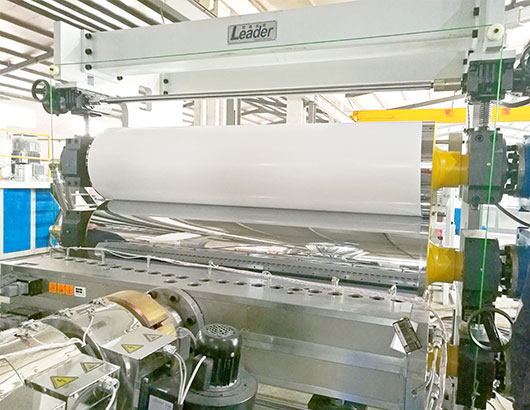

Product detail pictures:

Related Product Guide:

Adhering into the principle of quality, provider, performance and growth, we now have gained trusts and praises from domestic and intercontinental consumer for Wholesale Plastic Plate Machinery Supplier – PVC WPC Foam Board / Co-Extrusion Foam Board Extrusion Line – Leader , The product will supply to all over the world, such as: Cyprus, Mexico, Jordan, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We have been looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!