Wholesale Eva Film Extrusion Line – PC PMMA Optical films/sheets extrusion line – Leader

Wholesale Eva Film Extrusion Line – PC PMMA Optical films/sheets extrusion line – Leader Detail:

Main features of the line

1) Dehumidifying and drying system for to reduce the moisture of the raw material

2) Gravimetric dosing system for raw material handling is available.

3) Advanced screw and barrel structure design can realize the raw material good plasticization and stable pressure and reliable extrusion

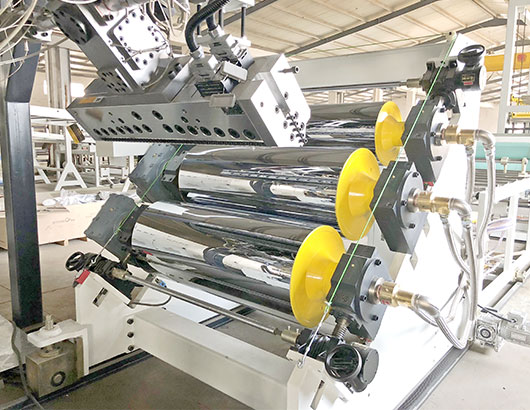

4) The precise three-roll calendaring system provides a guarantee for the mechanical and physical properties of the sheet. By changing roller calendars, the line can produce both high gloss smooth finish sheet and also matte finish sheets and other textured sheets as customized.

5) Automatic online thickness X-ray scanner gauge can monitor the sheets thickness at real time

6) The new high-speed automatic winding machine is equipped with an automatic correction system, which can automatically complete the winding and cutting actions, and the winding end surface is neat.

7) Advanced technology optimized the extrusion process and result in an excellent and stable products.

8) High flexibility of our lines, suitable for manufacturing a wide range of raw material and products types.

9) Complete automation of the extrusion line saved the labor cost and reduced the maintenance and processing cost as well.

10) Worldwide famous assembly parts, such as SHINI, MOTAN, JC TIMES, NORDSON EDI, SCANTECH, NORD, MAAG, GEFRON, NSK, ABB, SIEMENS etc.

Applications for the sheets

Automotive industry, communications, LCD for laptop, TV, mobile etc, sunglass, helmet, film switch for electronics, medicine packaging, cards, etc.

Main Technical Data

| Model | LSJ-100/36 | LSJ-120/35 |

| Suitable material | PC PMMA | PC PMMA |

| Product width | 915-927-1000mm | 1220mm |

| Product thickness | 0.125-0.175-0.25-0.3-0.55-0.6-1.2mm | 0.125-1.2-2mm |

| Sheets types | 0.125-0.5mm thickness in rolls | 0.5-2mm thickness in sheets pics |

| Die width | 1300mm | 1500mm |

| Max capacity | 200-250kg/h | 400-450kg/h |

Product detail pictures:

Related Product Guide:

We will constantly satisfy our respected customers with our good excellent, superior value and superior assistance due to we're additional experienced and far more hard-working and do it in cost-effective way for Wholesale Eva Film Extrusion Line – PC PMMA Optical films/sheets extrusion line – Leader , The product will supply to all over the world, such as: Honduras, Ukraine, venezuela, We have advanced production technology, and pursuit innovative in goods. At the same time, the good service has enhanced the good reputation. We believe that as long as you understand our product, you need to be willing to become partners with us. Looking forward to your inquiry.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.