Wholesale Barrier Sheet Extrusion Line Manufacturer – PP PE ABS Vacuum Forming Thick Sheet/Board Extrusion Line – Leader

Wholesale Barrier Sheet Extrusion Line Manufacturer – PP PE ABS Vacuum Forming Thick Sheet/Board Extrusion Line – Leader Detail:

Extruded sheets advantages and main applications

The extruded PP PE ABS boards are mainly used for vacuum forming purpose, featured with impact-resistance, corrosion resistance, high heat resistance, non-toxic and tasteless, smooth surface appearance, low density, light weight, easy processing, good dimensional stability, rigidity, good heat resistances, widely used for various fields.

PP/PE thick board: widely used for chemical industry, electronics, machinery, automobiles parts, medicine and also water treatment, outdoor entertainment facilities in park, and other fields.

ABS board: featured in excellent thermoplastic, flame retardant and high impact resistance, widely used for tops of cars and buses, instrument boards, backseat boards, car doors, window frame, out shell of the motorcycles, golf vehicles etc.

Features of this extrusion line

1) Advanced screw and barrel structure design can realize the raw material good plasticization and stable pressure and reliable extrusion. Hard screw and barrel, special structure design of screw is suitable for PP/PE material, 100% recycled material possible. The single screw extruder can be designed as vacuum degassing type or without based on clients’ requirements.

2) Hydraulic screen changer can effectively block the impurities from the raw material.

3) Imported Melt gearing pump is equipped to guarantee the raw material pressure more stable.

4) High quality specially designed T die head, adopts standard 2311A mould steel and strict polishing and precise ele-chromed.

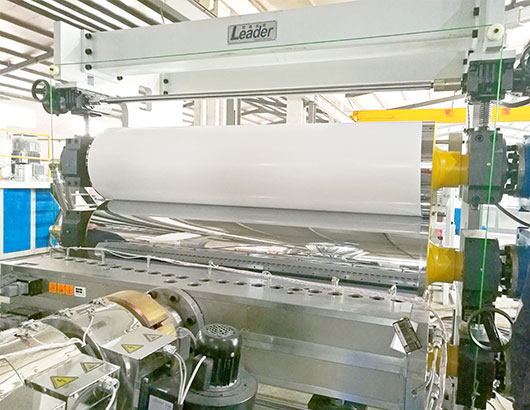

5) The three roller calendars can adopt horizontal type, oblique type, vertical type or other angles type designs to meet different types of sheets extrusion. The driving system of the roller calendars can be common reduced motor control or servo motors control.

6) Worldwide famous assembly parts, such as SHINI, MOTAN, JC TIMES, NORDSON EDI, SCANTECH, NORD, MAAG, GEFRON, NSK, ABB, SIEMENS etc.

7) Effective energy saving technology with a very low energy consumption.

8) Whole line adopts fully automatic Siemens PLC touch screen control; the electronic control equipment effectively optimizes the whole line operation and achieves high quality and high output.

Main technical data

| Model | LMSB120 | LMSB150 | LMSB-160 |

| Suitable material | PP PE ABS | PP PE ABS | PP PE ABS |

| Product width | 1220mm | 1500mm | 2000mm |

| Product thickness | 1-3mm, 3-30mm | ||

| Product structure | Mono layer, ABA, AB co-extrusion | ||

| Max capacity | 300-400kg/h | 400-550kg/h | 600-700kg/h |

Product detail pictures:

Related Product Guide:

We have our own sales team, design team, technical team, QC team and package team. We have strict quality control procedures for each process. Also, all of our workers are experienced in printing field for Wholesale Barrier Sheet Extrusion Line Manufacturer – PP PE ABS Vacuum Forming Thick Sheet/Board Extrusion Line – Leader , The product will supply to all over the world, such as: South Africa, Madrid, Ethiopia, With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in this field and other industries. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success! We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

We have been looking for a professional and responsible supplier, and now we find it.